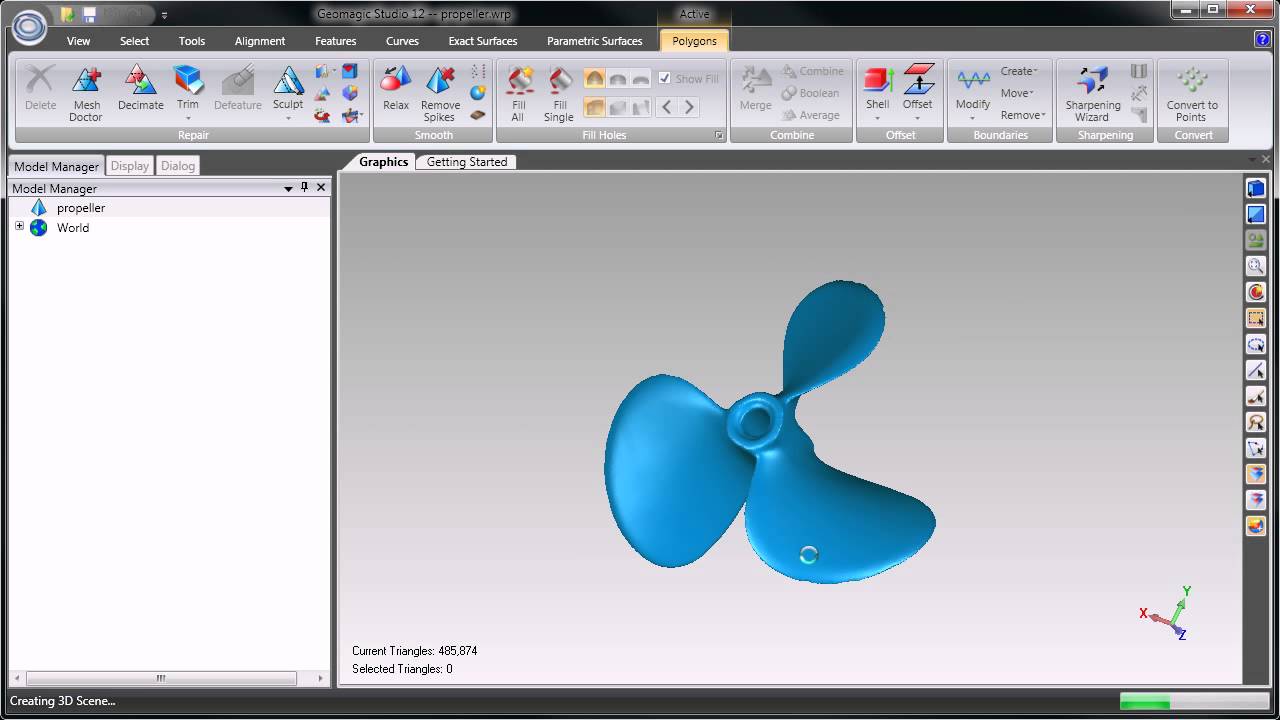

RESEARCH TRIANGLE PARK, N.C. – Geomagic announces a new version of Geomagic Studio software that adds powerful surface manipulation capabilities to its award-winning Fashion module while improving performance for point and polygon processing tools. Geomagic Studio is the world’s leading software for creating accurate 3D digital models from scan data of physical objects.

New in Fashion

The Geomagic Fashion module in Geomagic Studio 10x automatically identifies, analyzes and corrects imperfections in scan data to create high-quality geometric and freeform surfaces that can be further manipulated in CAD. This greatly reduces the time required to bring physical forms into the digital realm for mechanical design applications such as new design and reverse engineering. Major new features and enhancements to Geomagic Fashion include:

* Constrained surface-fitting capabilities for perfectly aligning surfaces and correcting

imperfections in the as-built model or scan data.

* Automatic surface extension and trimming capabilities for creating perfectly sharp

edges between neighboring surfaces, making edges and surfaces faster and easier to

manipulate downstream in CAD.

* Advanced tools that enable users to exclude regions of a mesh that deviate from the

desired surface classification, resulting in a more accurate representation of the digitized

part.

New automatic surface extension and trimming capabilities in the Fashion module for Geomagic Studio 10x create perfectly sharp edges between neighboring surfaces, making edges and surfaces faster and easier to manipulate downstream in CAD.

Better polygon models

- Geomagic Capture Scanner. The first scanning device that PADT recommends is the Geomagic Capture Scanner. A leader in price/performance, the Capture provides greater ease-of-use and accuracy compared to hand-held laser scanners at about the same price point.

- Artec Studio 12 and SOLIDWORKS license holders can now export 3D models directly into SOLIDWORKS by using the Geomagic professional plugin, one of the most advanced scan-to-SOLIDWORKS solutions on the market today.

What is Geomagic for SOLIDWORKS? Imagine being able to capture anything in the physical world and have a digital solid model of it in minutes. Geomagic ® for SOLIDWORKS is a reverse engineering software toolset that plugs directly into your SOLIDWORKS environment, giving you advanced capabilities to make tools, point clouds, and polygons more usable in your design process.

Geomagic Studio 10x also includes enhancements that improve performance and quality of point and polygon processing. An improved algorithm for registration helps users create more accurate point clouds from scan data, and a new decimation methodology produces smaller, yet still accurate, polygon models.

Geomagic Studio 10x provides major improvements that accelerate every step in creating intelligent, CAD-ready surfaces. The latest release features a new registration algorithm for more accurate point clouds, a new decimation algorithm for more efficient polygon models, and powerful new surface manipulation capabilities.

Front-end for Class A surfaces

Geomagic Studio 10x with Geomagic Fashion further speeds, automates and simplifies the workflow of transforming scan data into a Class A surface model. Its capabilities make it an ideal complement to design tools such as Autodesk AliasStudio.

Geomagic Studio 10x provides major improvements that accelerate every step in creating intelligent, CAD-ready surfaces. The latest release features a new registration algorithm for more accurate point clouds, a new decimation algorithm for more efficient polygon models, and powerful new surface manipulation capabilities.

“Geomagic Studio 10x with Geomagic Fashion streamlines what was previously a time-consuming and tedious process of moving from points to polygons to Class A surfaces,” says Karl Matthews, director of product management for Geomagic. “In conjunction with AliasStudio, it allows designers to bypass challenging modeling procedures and concentrate on the design process.”

Solutions for specific applications

Geomagic Studio 2014

Geomagic Studio 10x comes in three editions to suit the needs of mechanical design and medical/scientific markets:

* Geomagic Studio – Fashion Edition is the premier product for mechanical design

applications such as new design and reverse engineering. It includes Geomagic Fashion

for automatically extracting design intent from scanned physical object, providing the

fastest way to go from scanning to CAD-ready surfaces.

* Geomagic Studio – Shape Edition is designed for medical and scientific applications

where users want to create exact 3D replicas of organic objects such as bones or

historical artifacts. It includes the Geomagic Shape surfacing module for creating

water-tight NURBS surfaces.

* Geomagic Studio – Complete Edition is ideal for mechanical designers who want to

extract design intent from existing objects and perform FEA and CFD analysis on as-built

parts. This edition includes Geomagic Fashion for design work and Geomagic Shape for

creating models of as-built parts.

Geomagic Studio 2012

Geomagic 10x will be available in early 2009.

::Design World::

Geomagic Download

Description

Geomagic Studio 2013

| Geomagic Studio Create accurate digital models from physical parts |

| Geomagic Qualify Digitally inspect as-built versus as-designed parts |